| POWERPOINT |

| SCREW PUMPS |

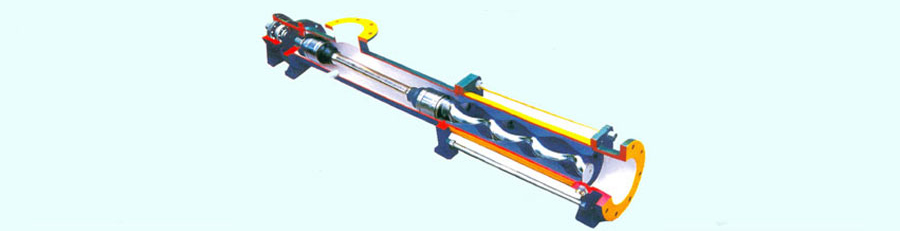

The pumping element comprises of a single external helix precision machined metal rotor and a double internal helix elastomer stator. As the rotor rotates eccentrically inside the stationary stator, continuous sealed cavities are formed 180 degrees apart which progress from the suction to the delivery end of the pump carrying the fluid to be pumped. |

||

|

||

|

| 'A' SERIES BARE SHAFT INDUSTRIAL PUMPS | ||

Apart from handling heavy duty materials under arduous conditions, 'A' range pumps will gently transfer delicate and shear sensitive products such as latex, thixotropic products and solids in suspension with minimum agitation and aeration. The series comprises a hollow shaft which shortens the length of pump and are of cast iron construction with alloy steel/stainless steel rotating parts. Shaft sealing is ensured by quality gland packing or mechanical seal. Rotor and Stator material combinations are available for pumping of highly abrasive or corrosive fluids.

User Industries: Coal Mines, Construction, Cosmetics, Detergents, Distillery, Dye Stuff, Effulent, Ediable oil, Fertilizer, Marine, Mining, Paper, Paint, Sewage, Sugar, Textile etc.

Fluids Handled: Acid, Acrylic Emulsion, Ceramic, Chemical Slurries, Dyestuff, Effulent, Emulsion, Explosive Slurry, Paint, Magma, Molasses, Oil Printing Ink, Solvents, Vegetable Oil, Viscose, Yeast etc. |

|

|

| 'AO' SERIES BARE SHAFT INDUSTRIAL PUMPS | ||

'AO' series single screw pumps are of cast iron construction with alloy steel/stainless steel rotating parts. Parts in contact with the fluid in stainless steel / Alloy Steel. Shaft sealing is ensured by soft gland packing or mechanical seal. Simple economy design. An integral motor base plate eliminates the requirement of a base plate, motor placed just above the bearing housing and driven by V belt pulleys thereby reducing the space requirement drastically.

User Industries: Construction, Cosmetics, Detergents, Distillery, Dye Stuff, Effulent, Ediable oil, Fertilizer, Marine, Mining, Paper, Paint, Sewage, Sugar, Textile etc.

Fluids Handled: Oils and water, Light Slurries, Light Creams, Hair oil, Shampoos and light Cosmetic creams. Deck Wash, Cooling & Lubricating Oil etc.

|

|

|

| 'ABH' SERIES BOREHOLE PUMPS | ||

The Borehole pump is the essence of simplicity in design, It is capable of handling sand laden water efficiently without due wear-tear to its pumping element. The designed rotor and stator are immersed below draw-down level in the bore or well . The drive head is located at ground level for easy inspection, maintenance and installation. Speed of the pump can be adjusted to match well yield. Provides advantage over irrigation pumps as it can be driven through motor, engine or even a tractor which enhance its benefits esp. in remote areas of frequent power cuts. 'ABH' series is available for 3" to 8" bores.

User Groups: Agriculture, Domestic & Industries.

Fluids Handled: Underground water for Drinking, Irrigation and Industrial use also. |

|

|

| 'AB' SERIES MONOBLOCK PUMPS | ||

'AB' range pumps provides an economic answer to many pumping duties, with high capacities & suction lifts. Somple design and construction provide extended pump life a& allow minimal routine servicing to be carried out without special facilities or skilled labour. Hygenic design eliminating product retaining pockers. Capable of handling sand laden water without undue wear. Wide range of material of construction is available.

User Groups: Domestic, Multistorey Flats, Construction sites, Confectionery, Cosmetics, Dairy, Edible Oils, Fruit Processing, Hotels, Hospitals, Ice Cream, Pharmaceuticals, Winery etc.

Fluids Handled: Oils and water, Drug Formulation, Light Slurries, Hair oil, Shampoos and light Cosmetic creams etc. |

|

|

| 'ANA ' SERIES INDUSTRIAL PUMPS | ||

'ANA' series pumps are used for a wide variety of pumping and transfer duties. They are found in tough rugged industrial application handling anything from abrasive slurries, aggressive or reactive chemicals, to viscous liquids, oils, or suspensions and aqueous solutions at elevated temperatures. These pumps consists torsion free metal-bonded stator for increased stator life, higher efficiency and per stage pressure. Simple Cast Iron construction with internal rotating parts of Alloy Steel/Stainless Steel depending on the fluids to be handled. Shaft sealing ensured by gland packing with Mechanical Seal Optional.

User Industries: Brewery, Ceramics, Chemical, Construction, Cosmetics, Detergents, Distillery, Effluent,Edible oil, Fertilizer, Marine, Mining, Oil exploration, Paper,Pulp, Paint & Vernish, Sewage treatment, Sugar, Soap & Detergents, Textile, Toiletries etc.

Fluids Handled: Acidic & Alkaline slurry, Acrylic Emulsion,Black liquor, Ceramic slurry, Chemical Slurries, Dyestuff, Effulent, Emulsion, Explosive Slurry,Glue, Paint, Magma, Molasses(all grades), Oil, Petroleum jelly, Printing Ink, Solvents, Sodium Silicate, Sulphited Suger juice, Vegetable Oil, Viscose, Yeast etc.

|

|

|

| 'AP ' SERIES INDUSTRIAL PUMPS | ||

'AP' series pumps are fitted with a free-fitting stator with constructional features including Cast Iron bearing housing, NS/SS fabricated pump housing. All rotating parts are of SS or other corrosion resistance special alloys. Rotor and Stator material combinations are available for pumping of highly abrasive or corrasive fluids. Shaft sealing ensured by gland packing with Mechanical Seal optional.

User Industries: Brewery, Ceramics, Chemical, Construction, Cosmetics, Detergents, Distillery, Effluent, Edible oil, Fertilizer, Marine, Mining, Oil exploration, Paper,Pulp, Paint & Vernish, Sewage treatment, Sugar, Soap & Detergents, Textile, Toiletries etc.

Fluids Handled: Acidic & Alkaline slurry, Acrylic Emulsion,Black liquor, Ceramic slurry, Chemical Slurries, Dyestuff, Effulent, Emulsion, Explosive Slurry,Glue, Paint, Magma, Molasses(all grades), Oil, Petroleum jelly, Printing Ink, Solvents, Sodium Silicate, Sulphited Suger juice, Vegetable Oil, Viscose, Yeast etc. |

|

|

| 'AYT' SERIES HYGENIC PUMPS | ||

'AYT' series single screw pumps are designed specially for hygienic applications. All internal contours are designed to be swept away by product flow or by detergents when 'in-line' cleaning. All metallic parts in contact with the fluids are in smooth finish stainless steel, and stator is of non-contaminating food grade elastomer viz. Nirtile, EPDM, Silicon and Viton. Shaft sealing is ensured by hygienic quality gland packing or mechanical seal. These pumps are available in IDF/ SMS or equivalent suction discharge end connections.

User Industries: Bakery, Brewery, Confectionery, Cosmetics, Diary, Ediable Oils, Fruit Processing, Winery Food Processing, Ice Cream, Malt & Cocoa, Pharmaceuticals etc.

Fluids Handled: Apple Pulp, Amla Pulp, Chocolate Mix, Minced Meat, Beer, Beverages, Butter Oil, Cream, Curd, Fruit Pulp, Glucose, Jam, Liquor, Squashes, Sugar Syrup, Medical Formulations, Yeast, Yoghurt etc. |

|

|

| 'AYOT' SERIES WIDE THROAT PUMPS | ||

'AYOT' Pump processes an ideal pumping principle for handling substances of extreme consistency. To gain full advantage of its versatility for such duties this pumping technique enables efficient & easy pumping of non- Newtonian or plastico-viscous fluids. To achieve this function the pump is fitted with alloy steel/stainless steel Auger cum coupling rod which pushes viscous substances into the pumping element. For corrosive and hygienic applications product retaining pockets are completely eliminated, avoiding bacteriological and chemical contamination. MOC available in wide range..

User Industries: Bakery, Brewery, Confectionery, Diary,Dye Stuff, Explosives, Ediable Oils, Food Processing, Malt & Cocoa, Meat Processing, Paper & Pulp, Paint & Vernish, Sugar & Starch, Soap & Detergents etc.

Fluids Handled: Asbestos Slurry, Butter, Cake Mix, 'Chyawanprash', Clay Slurry, Explosive Slurry, Fruit or Vegetable Mash, Printers Ink Paste, Putty, Starch Slurry, Yoghurt and other material regarded ' Unpumpable'. |

|

|

|

||

| Powerpoint Range of Spare Parts: Powerpoints Pumps are known for their widest range of spare parts for any Indian or Foreign brand progressive cavity pumps. Powerpoints parts are produced to ISO 9001:2000 using high quality materials. heat treatment processes and coatings. Strict quality procedures ensure the control of accurate manufacturing tolerances, resulting in dimensionally interchangable parts. These processes give you increased abrasion and corrosion resistance to ensure every replacement part lasts longer, yet still offering you an economical product. | ||

|

||

| 'PNA' PUMP SERIES- TECHNICAL DATA | ||

|

||

| The suction lifts quoted relate to water at 15 degree C and 762 mm barometer when operating at the lowest speeds listed. The date above is related to pumps(without circulating bypasses) for liquids of similar viscosity to water. The speeds selected in this table are for standard electric motor speed. Reduced speeds should be chosen for viscous are abrasive fluids and extreme conditions. Capacity is approximately proportional to the speed of the pump. | ||